Ultraviolet Light Protection and Stabilization Masterbatch

Ultraviolet (UV) light can be particularly damaging to the polymer backbone of polyolefins, and for UV-exposed products. To varying degrees, UV light especially affects products that spend most or just any of their service lives outdoors. UV can cause yellowing or otherwise unintended color changes, while also degrading the materials physically, causing surface chalking, cracking, loss of gloss, and lower mechanical properties. Moreover, UV light that is allowed to pass through a packaging material may damage the product contained inside, even lowering the nutritional value of the food or beverage. Thus, UV-blocking, -absorbing, and -stabilizing additives receive much deserved attention from additives developers and users.

UV Degradation of Polyolefins

The initiation of polymer degradation via UV light depends mainly on the presence of UV-absorbing species (chromophores) mixed in with the polymer. Since saturated polyolefin molecules do not themselves absorb much UV light directly, the most damaging UV effects are from absorption by chromophores such as catalyst residues, pigments, processing aids, flame retardants, or generally any organic molecules containing double bonds. These molecules release some of the UV energy they absorb by breaking bonds and releasing free radicals, which begin a degradation cycle similar to the autoxidation processes.

Given all this potential degradation from UV, without some sort of internal protection or stabilization, polyolefins can lose properties relatively quickly under sunlight or UV exposure. For instance, high-density polyethylene (HDPE) in the form of 1.5-mm plaques can lose 80% of its impact strength in just 2000 h of accelerated weathering (with UV exposure).

Different polyolefin structural forms react differently to UV. Highly branched low-density polyethylene (LDPE) tends to degrade more readily than linear low-density polyethylene (LLDPE) or HDPE. Overall, degradation takes place more easily within the amorphous phase of a polymer than in the crystalline phase. Moreover, PE and PP photo-oxidation behaviors are different enough that the same additives approach for protecting PE may not work the same in PP, even in the same applications. A common stabilizer in a thin section of PE can be far more effective there than when it is used in thin PP. Likewise, other stabilizers may be more or less effective, or change a product’s color more or less, when used in PE or in PP. And even different forms of PP—homopolymer and copolymer—can differ in their sensitivity to UV when using the same stabilizer.

There are several ways in which additives prevent or interrupt the degradation processes initiated by UV. Bulky additives act as shields, physically screening or blocking UV light from penetrating deeply into the polymer. These additives and other organic chemicals also partially absorb the UV energy themselves (or the UV energy stored by chromophores) and release it in ways that are not harmful to the polymer. UV stabilizers can interrupt the degradation cycle itself by scavenging free-radical species or the peroxides they create.

Common Commercial UVAs and HALS-Based Light Stabilizers

| Polyolefin Application Notes | Commercial Grade Example | Generic Designation |

| Food use compliant | Chimassorb 81, Cyasorb UV-531 | UVA-1 |

| Molded PP/TPO; low metal interaction | Cyasorb UV-2337 | UVA-2 |

| Food use compliant | Tinuvin 326 | UVA-3 |

| Low volatility, high solubility in polyolefins | Cyasorb UV-1164 | UVA-4 |

| Nonfood use compliant | UVA-5 | |

| Food use compliant | Uvinul 3030 | UVA-6 |

| Molded PP | Tinuvin 770 | HALS-1 |

| Low molecular weight; color and gloss protection; synergies with high weight HALS and UVAs | Cyasorb UV-3853 | HALS-2 |

| Low molecular weight, monomeric; FDA food contact approved | Uvinul 4050 | HALS-3 |

| Lower basicity | HALS-4 | |

| For thin PP | HALS-5 | |

| Liquid product | Tinuvin 123 | HALS-6 |

| High molecular weight, less migratory | Chimassorb 944 | HALS-7 |

| High molecular weight and oligomeric; low volatility/migration | Tinuvin 622 | HALS-8 |

| High plus low molecular weight HALS | Tinuvin 791 | HALS-1+

HALS-7 |

| For tapes and thin products | Tinuvin 783 | HALS-7+

HALS-8 |

Factors Determining Stabilizer Selection

- Part thickness: Thin films, sheets, and fibers may be more susceptible to damage by UV since a greater proportion of their resin bulk lies near the surface. Accordingly, nonextractable, high molecular weight stabilizers are more useful in thin products. UVAs are less effective in thin sections, since they require a significant path length to be effective. Conversely, for thick sections, UVAs and fast-migrating, low weight stabilizers are useful for protection at the surface, where the effects of UV light are the greatest.

- Migration and extraction: Polar stabilizer molecules are not compatible with nonpolar polyolefins, leading to the potential of migration and extraction losses, especially with low molecular weight monomeric stabilizers. However, for intense outdoor exposure applications, it might be desirable to use stabilizers that migrate toward the surface of the product. It is near the surface where their effects are most needed, but these low weight molecules can bloom and be lost over time, or be absorbed or adsorbed by fillers such as calcium carbonate or talc. Thus, a more reactive but more extractable HALS such as HALS-1 may be less effective than a less reactive but more soluble HALS like HALS-2 .

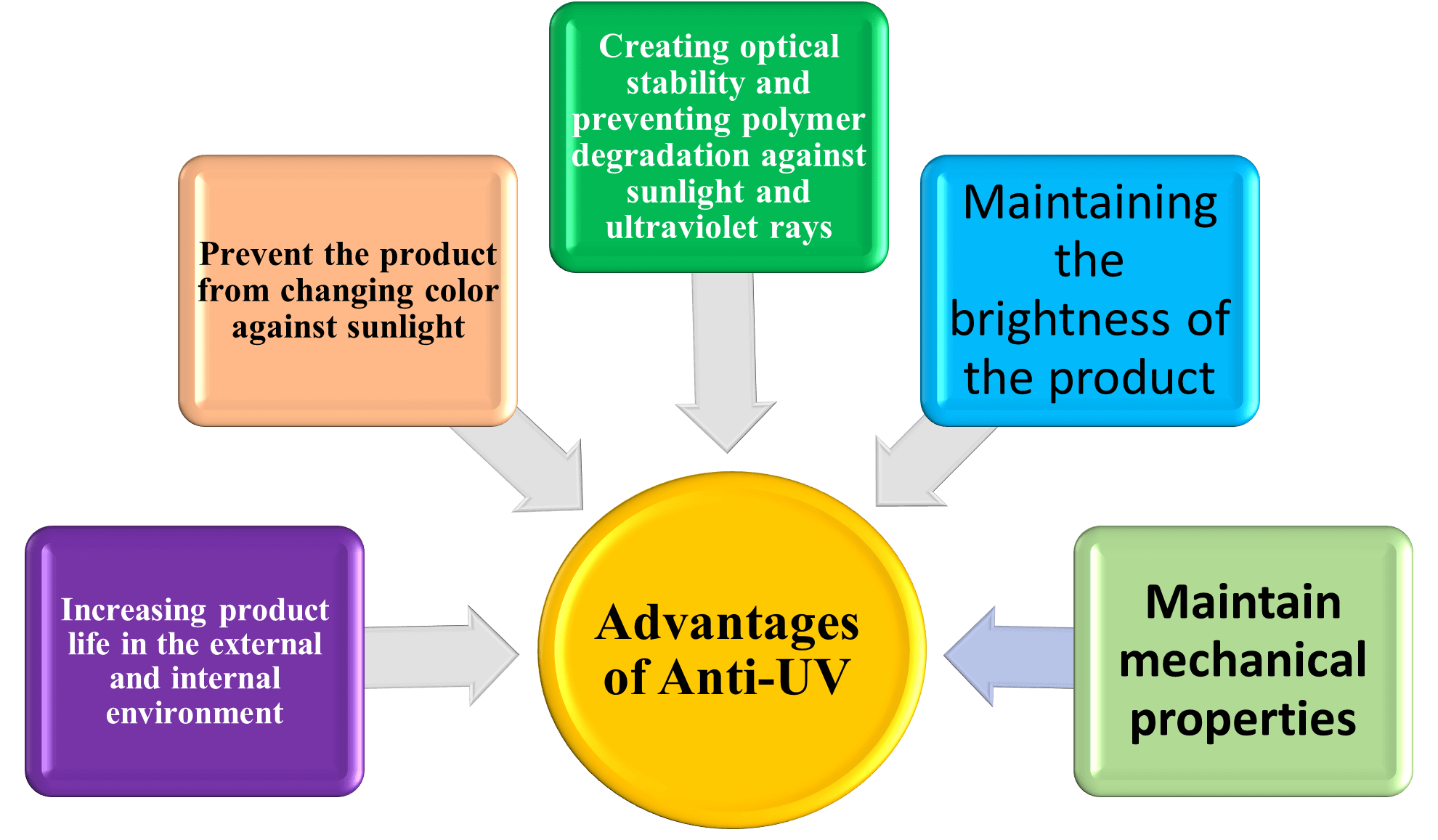

Advantages of Anti UV Masretbatch:

You can contact our experts to inquire about the price and buy anti UV masterbatch