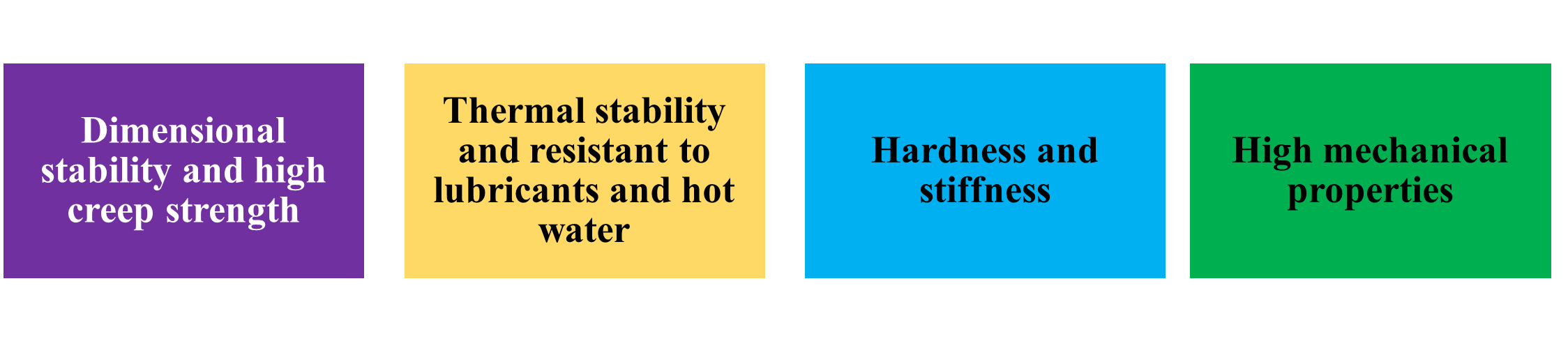

Polyamide is strengthened by the addition of glass fibers. The addition of glass fibers decreases properties such as elongation at break and impact resistance. By combining glass fiber-reinforced polyamide with an impact modifier, it is possible to enhance the impact strength and elongation at break of the material.

Glass Fiber

Today, fibers are one of the most widely used materials in the industry. Compared to other fibers such as carbon fibers, glass fibers possess excellent mechanical properties. Glass fibers are used to reinforce polymer products in order to achieve good stability and lightness.

Glass fiber properties

- Increased strength: Glass fiber has higher tensile strength than steel wires while being lighter at the same time.

- Dimensional stability: glass fibers are not sensitive to changes in temperature and humidity and have a low coefficient of linear expansion.

- High thermal resistance

- The surface area-to-weight ratio of glass fibers makes them an excellent thermal insulator. Consequently, they have become very popular in the construction industry as a result of this very good feature.

- Excellent fire resistance: Since fiberglass is a mineral, it is naturally non-combustible. It does not spread or support flames, and when exposed to heat, it does not emit smoke or toxic substances.

- Good chemical resistance: Glass fibers are chemically resistant to a wide range of chemicals.

- Excellent electrical properties: glass fibers have high dielectric strength and low dielectric constant. Even at low thicknesses, it is electrically insulating.

- Compatibility with organic matrices: Glass fibers have different sizes (surface treatment) and can be combined with variety of materials

- Affordable

Advantages of PA6 reinforced with 30% glass fiber

Application of PA6/ GF

DanPolymer’s PA6 reinforced with Glass Fiber

| Product | Description | TDS |

| Dan-PA6-W30G | PA6 reinforced with 30% glass fiber | |

| Dan-PA6-W40G | PA6 reinforced with 40% glass fiber | |

| Dan-PA6-W50G | PA6 reinforced with 50% glass fiber |