Colorants can make relatively inexpensive commodity materials such as polyolefins appear to be (superficially at least) more than just the sum of their parts. Polyolefins have relied on their colorability to make products more aesthetically pleasing to use, or simply to draw more visual attention to a product. Product differentiation may perhaps be the main reason polyolefins are colored, whether for short-lived packaging or color-matched, durable, assemblies such as automobiles or playground equipment. and the cost and paint avoidance are motivators to use colorant additives: a large portion of the cost of a plastic automobile part comes from the painting operation.

There are several options for inducing varieties of colors into an otherwise naturally colorless or translucent polyolefin resin product. Colorants are normally used in the form of solid pigments submicron-scale organic or inorganic particles dispersed throughout the resin and unique forms of pigments or additives can attract the eye more by mimicking metals or by reflecting or re-emitting light in interesting ways. Formulating for color depends heavily on answering questions about whether the polyolefin will be used for a long-lasting durable application or a relatively short-term packaging application.

Typical of colorant:

Pigments are usually classified into three groups:

organic-dyes

organic-dyes

There are two types of dye: natural pigments and synthetic pigments. these colors have a small particle size. One of the advantages of this pigment is that it has a high level of coloring power and is reasonably priced. In spite of that, it has a short shelf life and fades over time. In addition to having the ability to dissolve in plastics, they can also be used for coloring transparent materials.

organic-pigments

organic-pigments

As pigments are not soluble in polymer, they need to be dispersed within the polymer matrix. The pigment has a longer life span than other pigments. The material absorbs light, but it is not transparent, so it is opaque. Phthalocyanines are one of the most important organic pigments. It is composed of green, blue and copper phthalocyanines, the latter of which is a blue pigment that has excellent resistance to a wide variety of factors.

inorganic-pigments

inorganic-pigments

Mineral pigments can have a wide range of colors, including white, black, and colored pigments. A common mineral pigment for white color is titanium dioxide and a common mineral pigment for black color is carbon black. In addition to iron oxides in red, yellow, green, and blue, cadmium oxides in yellow, and chromium oxides in blue, pigments that contain red lead, red cadmium, lead chromate, or cadmium, are also mineral pigments and are considered coloring agents.

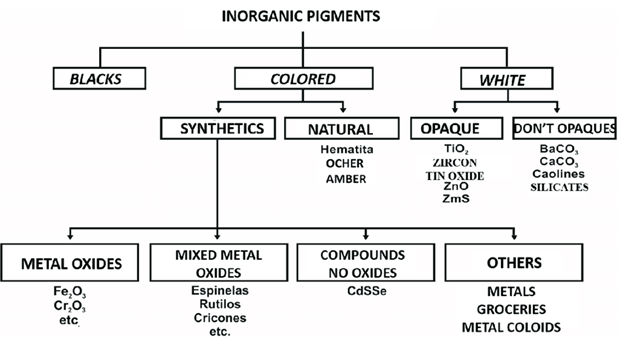

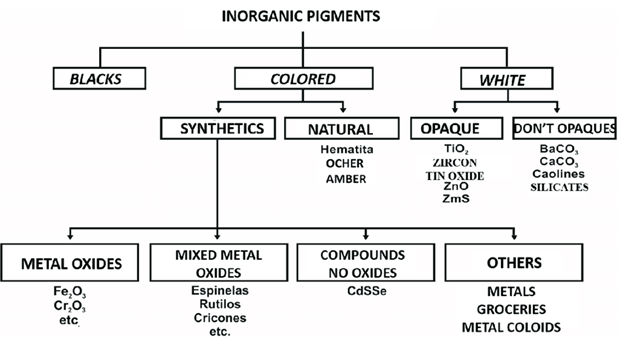

Mineral pigments are one of the most common pigments used in the industry today. Generally, mineral pigments are made up of metals and metal salts. Due to their low price as well as their good resilience to weathering, these pigments have been gaining attention in recent years. However, it is important to note that one of its disadvantages is that the color is dull and does not have a high gloss when it comes to finishing. Mineral pigments can be classified into the following types:

Buy color masterbatch

Masterbatch is one of the most common uses for masterbatch in the manufacturing of colored plastics. Color masterbatch is used in various industries such as film and packaging, pipe, textile, household appliances such as the body of household appliances, construction equipment such as socket switches, injection parts, and automobiles. Dan Polymer has the ability to produce different colors and can make the color you need.

If you would like to buy a color masterbatch, you can call 02158381200 for consultation and get the price color masterbatch.

organic-dyes

organic-dyes organic-pigments

organic-pigments inorganic-pigments

inorganic-pigments