Desiccant masterbatch

Masterbatch dryer or desiccant is a new type of functional masterbatch that is made to remove moisture from polyethylene and recycled PP. In addition, it solves the moisture problem when the masterbatch filler (additive to reduce cost) is much more than the range used. Fish eye defects can occur in products made with moisture-absorbing materials. Desiccants can help prevent these problems. Masterbatches containing desiccants may also reduce fish eye defects when raw materials are stored in high-humidity areas. The maximum amount of masterbatch filler grade that can be used in blown film production is 15 to 20%. Furthermore, 85 to 80% of the remaining materials are resins, plastics, and additives. Fish eyes or melt fractures will appear if more than 20% is used. Desiccant masterbatch helps remove moisture and reduces oxidation during polymer recycling.

Advantages of desiccant masterbatch:

- Add more filler

- Improves surface gloss

- Increases strength

- Increases production rate

Application of desiccant masterbatch:

- Handle plastic bags

- Agricultural film

- Bin bags

- Recycled polymers processing

- Injection processes

- Thermoformed sheets

- Corrugated pipes

- It is widely used in PE as well as PP recycling materials, as well as in wetting plastics for the blowing process and for injection.

- A wide range of applications for PE as well as PP recycling materials as well as the wetting plastic that has the highest demands for blowing, injection and sheeting

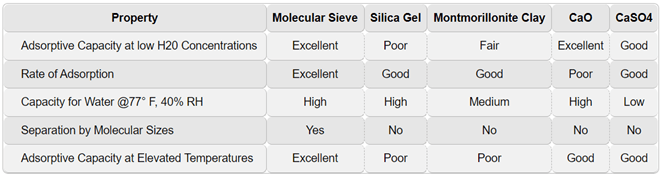

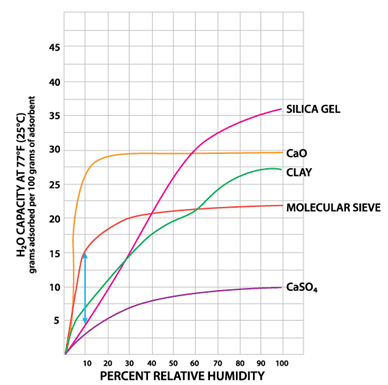

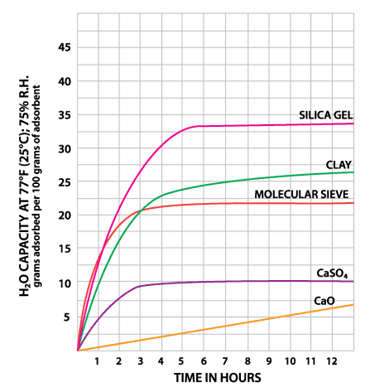

These masterbatches generally consist of mineral moisture-absorbing agents in a polyethylene matrix. Several mineral moisture absorbents are available, such as silica gel, bentonite clay, calcium oxide, and calcium sulfate.

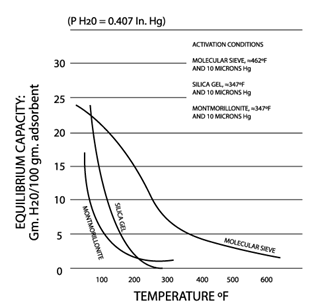

A comparison of the properties and performance of different moisture-absorbent materials can be seen in Table 1 and Figures 1 to 3:

RECOMMENDED DOSAGE

Average dosage 1-3%

STORAGE & HANDLING

Pre-drying of Desiccant masterbatch may be required. Avoid overheating.

If you would like more technical information or to get the daily price of desiccant masterbatch and buy Desiccant Masterbatch, please contact our sales experts.