As slip agents act by reducing friction between the film and the process equipment, they act similarly to antistatic agents and release the film from the mold. To improve the efficiency of these materials, these agents must be incompatible with the polymer. Therefore, they may migrate to the surface after cooling the melt. For film production, there are various slip agents, but the most common are as follows:

- Fatty acid primary amides such as Urocamide (melting point around 81-83°C),

- Olamide (melting point about )73-78° C),

- Stearamide (melting point about )102-101°C),

ethylene bis-stearamide (EBS) (melting point about 143°C), which is more thermally stable.

| Typs and chemical Formula | ||

| Melting Point (°C) | Formula | Typs |

| 66-72 | CH3(CH2)2-CH=CH-(CH2)2-CONH2 | Oleamide |

| 79-85 | CH3(CH2)2-CH=CH-(CH2)11-CONH2 | Erucamide |

| 98-104 | CH3(CH2)14-16-CONH2 | Stearamide |

Erucamide, oleamide, and stearamide are primary amides that can modify the surface of polyolefins to reduce friction coefficients and stickiness. During the process, amides migrate to the surface, so the lysing agent is chosen and concentrated according to the surface properties. As a result, these materials are usually combined with anti-caking or adhesion agents such as silica or talc, which have a positive synergistic effect. Additionally, stearamide can be used as an impact modifier and process aid in ABS.

The following points are important when it comes to using fatty acids as slip agents

- The migration of olamide is much faster than that of erucamide, so it is typically used for smooth surfaces where a low friction coefficient is required in a short amount of time.

- The lower vapor pressure and volatility of erucamid allow it to produce a friction film on the surface of the polymer. Thus, it creates a friction film at a slower rate. For this reason, it is one of the products that has been widely used in applications that require a higher process temperature to reach the specified results. In addition, it stays on the surface for a significantly extended period without smoking.

- Stearamide is often used in conjunction with erucamide or oleamide when film clarity and anti-blocking characteristics are of critical importance.

Advantades of Slip Masterbatch

- Reduced friction between films, as well as friction between films and parts made of metal

- It improves the quality of the product and increases the processability.

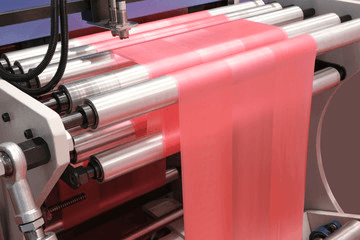

- It improves the speed of polyolefin film production.

- Due to the reduction in friction coefficient, it improves the processing ability of the packaging industry.

Application of slip masterbatch:

- Single layer and Multi-layer PE Films

- Agricultural films

- Molding

- A slip additive Master batch is a highly recommended additive for injection molding processes, as it can be used as a mold release agent

Usage:

The dosage is 1% to 6% depending on the end-use application. Below is our ideal recommendation

- For Low Slip 1% to 2%

- For Medium Slip 2% to 4%

- For High 4% to 6%

Slip masterbatch is produced in several grades by respected manufacturers, so if you consult with our expert experts and know exactly what you need, you can buy Slip masterbatch. Additionally, technical information is provided with this product. Our experts can answer your questions about the slip masterbatch price and buy it.