The use of a masterbatch features widely in compounding and with different polymer materials. A masterbatch usually incorporates a high loading of up to 60% by weight of one or more additive ingredients dispersed in a carrier polymer. The uniformity of the finished product is largely dependent upon the degree of dispersion of the masterbatch in the main polymer during melt processing. However, the performance of the masterbatch depends on the relative magnitude of its viscosity compared to that of the host polymer. Other parameters such as particle size and miscibility of the ingredients also play an important role.

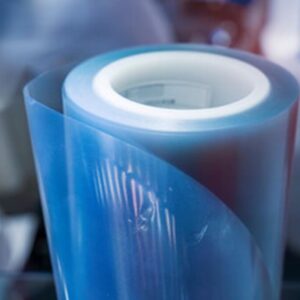

Color masterbatch

A color preparation is composed of plastics as carriers, colorants, and additives. Additives can be incorporated into plastics in two different ways. One possibility is to incorporate the additive in the color preparation, which is preferred when the required concentration of the additive is relatively low in the final part. If a high concentration is necessary the additive must be added directly at the plastics manufacturer’s plant; examples are fillers and flame retardants. The concentration of filler can reach 60%.

Additive masterbatch

Most polymers contain quite complex additive systems which are incorporated during manufacture to impart beneficial properties during manufacturing operations, e.g., protective antioxidants, slip agents, etc., and during end-use, e.g., antioxidants, ultraviolet (UV) stabilisers, plasticisers and antistatic agents, flame retardants, antioxidants and thermal stabilisers. The first stage in the examination of a polymer, either from the point of view of identifying the polymer or identifying and determining additives present must be to separate gross polymer from gross additives. It may then be necessary to separate the gross additive fraction into individual additives by a chromatographic procedure in order to facilitate the identification of individual additives.

Separation of gross polymer from gross additives is necessary so that examination of the

polymer is not affected by interference from the additives present and also vice versa.

Many different procedures have been studied for the removal of gross additives from the

polymer and some of these are discussed next.