PE is quite viscous in the molten state and can be easily fused to itself. This feature allows PE pipe and fittings to be fabricated by the thermal fusion of separate components. Thermal fusion is also the basis for the butt-, socket-, and electro-fusion processes, which are used for the joining of PE fittings to pipe. To protect PE against thermal and oxidative degradation during fabrication and ensure a long shelf and service life, PE is always compounded with a small number of additives. Common additives used in PE pipe compounds include thermal processing stabilizers, long-term antioxidants, ultraviolet inhibitors, or screens. Other additives such as pigments can also be added to modify the appearance or physical properties of the polymer. PE pipe resins are generally available to the pipe and fittings manufacturer in the form of natural pellets, whereby all required ingredients except for pigment are premixed and pre-dispersed into the base polymer. These pelletized compounds are commonly delivered to the piping manufacturer by hopper trucks or tank cars, off-loaded into silos, and transferred to the fabricating equipment by pneumatic conveying systems. The natural pellets are then mixed with an approved color concentrate at the pipe or fitting production site to result in an appropriately colored finished product.

Pipe manufacture

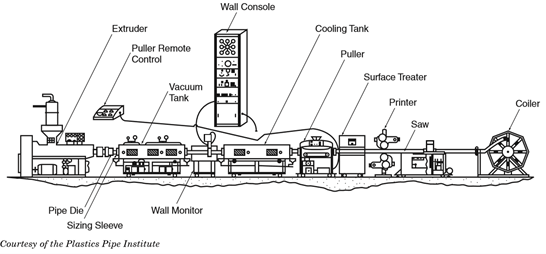

PE pressure pipes are manufactured by the extrusion process, whereby molten polymer material is continuously forced through an annular die by a turning screw. As the screw rotates, the flights on the screw continually convey material closer and closer to the die. The pipe is shaped as it exits the die and into the downstream equipment. Although simple in concept, the extrusion process used in the manufacture of plastic pipe employs a series of fairly sophisticated equipment that reliably and continuously performs the functions of feeding, melting, and mixing the material, delivering it to the die at appropriate and consistent conditions, accurately shaping and sizing the pipe, and cooling and cutting or coiling the product to precise lengths. As illustrated in the below Figure this series of equipment, commonly referred to as an extrusion line, generally consists of the extruder, the pipe die, sizing and cooling tanks, pipe puller, saw, and take-off equipment.

The die shapes the extrusion melt into a cylinder of slightly greater size than the final pipe product. When the PE melt exits the die, it is still molten, but the high viscosity of the material allows it to retain its shape. The final dimensions of the solid pipe are set by the sizing and cooling operation downstream of the die. Sizing is accomplished by pulling the hot PE cylinder through an accurately bored sizing sleeve that fixes the pipe’s outside diameter. The pipe’s outer surface is tightly held against this sleeve by applying either vacuum on the outside of the pipe or internal pressure on the inside of the pipe. While the pipe is being sized, it is also being cooled with water to set the outside diameter. The pipe must be cooled even after the outside diameter has been set to remove heat stored in the pipe wall. To accomplish this, one or more cooling tanks are set up downstream of the sizing sleeve/tank, and the pipe is pulled through each.

Fittings manufacture

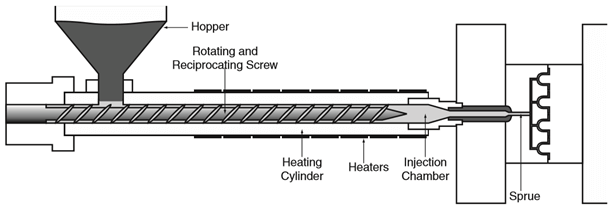

Plastic pipe fittings, because of their complex geometry, are generally manufactured by the injection molding process. This process is similar to extrusion in that the major operational steps are the same: mixing and melting of the material, then shaping and sizing, and finally cooling the part. While these steps are continuous in extrusion, they are performed cyclically in injection molding.

Fittings can also be fabricated using the thermoforming process by heating a section of pipe and using a forming tool to reshape the heated area. Examples are sweep elbows, swaged reducers, and forged stub ends. The area to be shaped is immersed in a hot liquid bath and heated to make it pliable. It is removed from the heating bath and reshaped in the forming tool. The new shape is held until the part has cooled. Very large diameter fabricated fittings (> 12 in. in diameter) require special handling during shipping, unloading, and installation. Precautions should be taken to prevent bending moments that could break the fitting during these periods. These fittings are sometimes wrapped with a reinforcement material, such as fiberglass, for protection. Reinforcing material is used only for mechanical protection, not to increase the design pressure rating of the fitting.

Quality Control Testing

PE pipe manufacturing is a continuous process. Therefore, the pipe producer generally monitors those process control variables that are determined as quality critical. Detailed records of these production variables are kept as a means to monitor the pipe production process thereby ensuring the quality of the pipe. Additionally, QC tests are conducted on the pipe during production on a regular basis to further ensure the quality of the finished product. These tests include but are not limited to the following:

- Pipe diameter, wall thickness, ovality, and length are periodically measured in accordance with ASTM D2122 to ensure compliance. All fittings also are periodically checked for proper dimensions and tolerances.

- All pipe, tubing, and fittings are routinely inspected to ensure that they are homogenous throughout—free of visible cracks, holes, foreign inclusions, blisters, dents, or other injurious defects. They are also checked to ensure that they are as uniform as commercially practical in color opacity, density, and physical properties.

- Pressure tests

Advantages of PE Pipe

Application PE pipe

- water supply networks

- sewage networks

- Drainage networks

- Fluid systems and industrial sewage

- Drip and sprinkler irrigation system

Polyethylene pipe compound of Dan Polymer Company

| Product | Description | TDS |

| DAN-PE-BP | Black PE compound for Pipe |