ABS

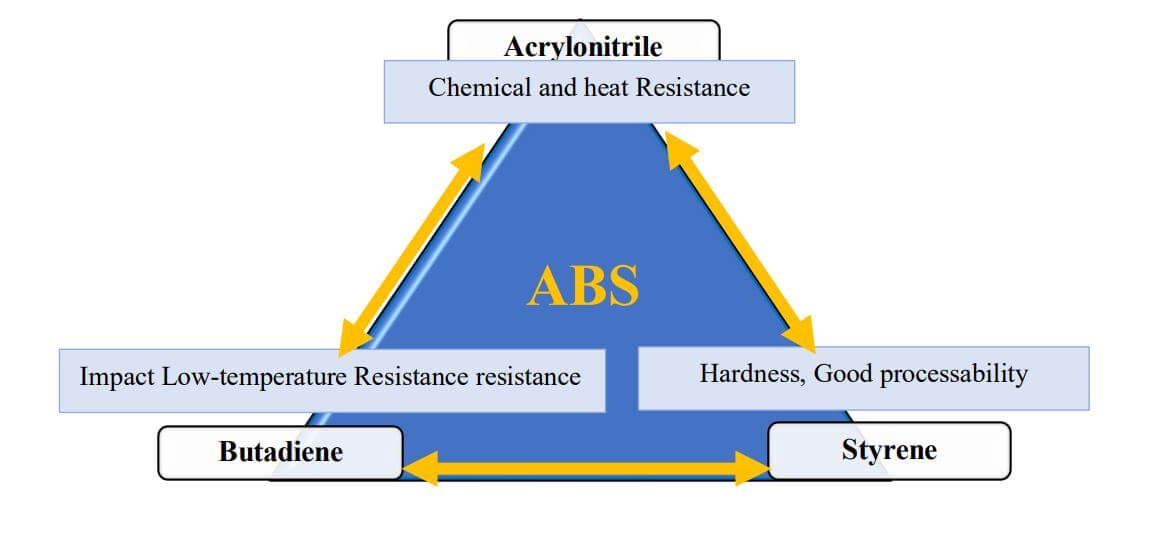

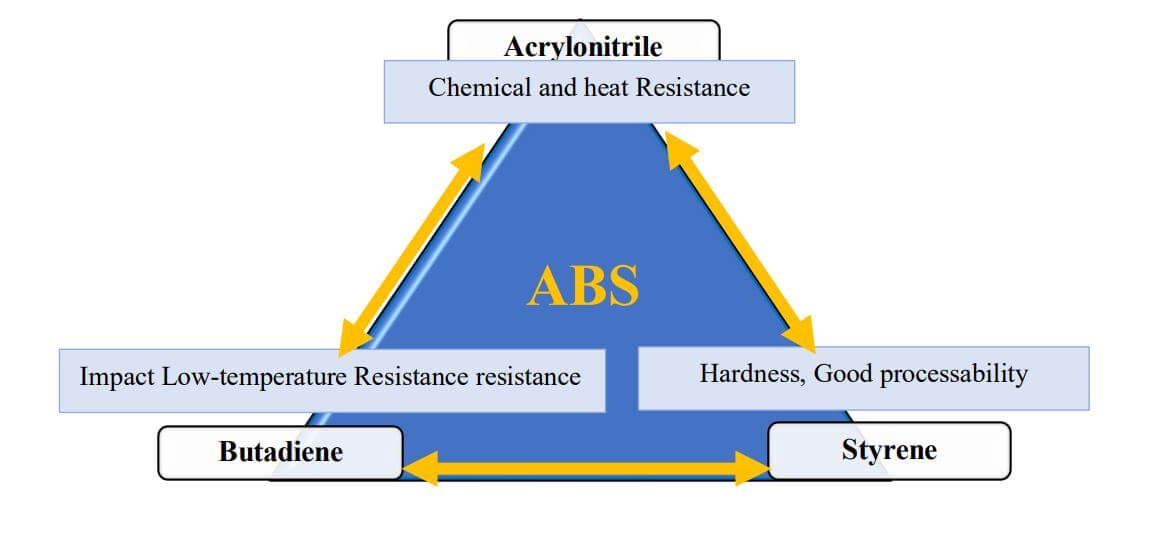

One of the most widely used polymers in the world is acrylonitrile butadiene styrene. ABS is a thermoplastic containing three monomers: styrene, acrylonitrile, and butadiene. Butadiene provides rubbery properties, while the butadiene chains are UV-degradable. Strength and chemical resistance are provided by the acrylonitrile component, while hardness and processability are provided by the styrene component. Additionally, acrylonitrile and styrene are compatible with other polymers because of their polarity. Different grades of ABS can be made by varying the percentages of styrene, acrylonitrile, and butadiene or by combining it with other polymers. Below is a diagram showing how each monomer influences ABS’s properties:

ABS compound

Compounding is the use of additives such as stabilizers, lubricants, colorants, low-cost inorganic chemicals and so on., to replace part of the polymer without compromising its mechanical properties and processing characteristics. Therefore, the economy of the material can be substantially increased in this way.

ABS has excellent properties such as high impact resistance, dimensional stability under temperature variations, chemical resistance, color acceptability, stiffness, and hardness. Various additives such as flame retardants, heat stabilizers, UV stabilizers, pigments, and flame retardant additives are combined with ABS granules to form ABS compounds. Thus, ABS products can be customized according to the customer’s needs.

Application of ABS compound

Its many applications are housings for household products, electronic enclosures, automotive parts, pipe fittings, toys, etc.

Buy ABS compound

You can buy ABS compounds by contacting sales experts. It is possible to prepare the desired ABS compound according to your product. To find out the daily price of ABS compound, please call number 021-58381200.